In order to win this inevitable battle and fight against COVID-19, we must work together and share our experiences around the world. Join us in the fight against the outbreak through the Global MediXchange for Combating COVID-19 (GMCC) program. Apply now at https://covid-19.alibabacloud.com/

By Cheng Yue from e-works.

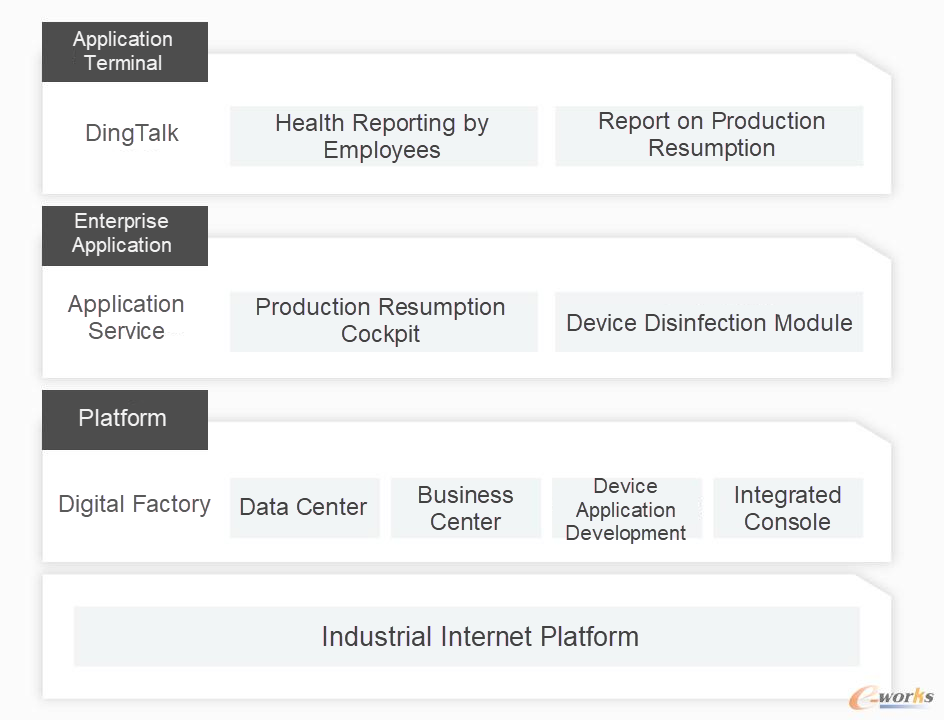

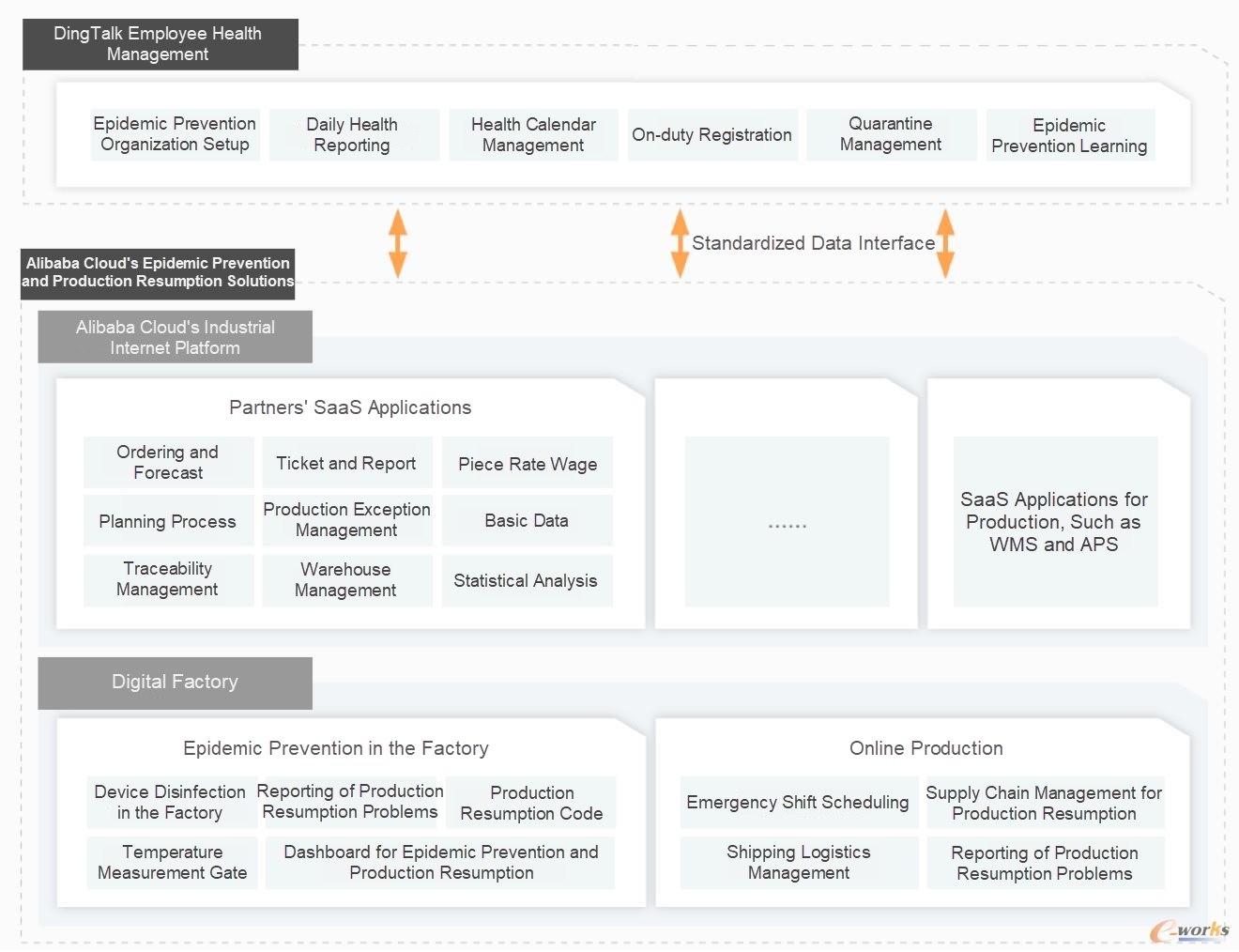

Manufacturing enterprises have been under great pressure during the COVID-19 outbreak in China and all around the world. The progress in resuming and ramping up production in the next few weeks is key to keeping enterprises afloat. Alibaba Cloud's Industrial Internet platform teamed up with DingTalk, Alibaba's work collaboration and instant messaging software, and other partner businesses to launch a lightweight SaaS solution for production resumption in the manufacturing industry. The proposed solution combines several cloud computing technologies, particularly IoT, big data, and mobile technology to provide eight management modules that are centered on people, machines, materials, methods, and procedures, with the end goal of helping manufacturing companies resume production as quickly as possible while also doing so in a safe and prudent way.

Ningbo Hongda Motor Die Co., Ltd. is a private company that has been operating for more than 30 years. Specializing in the development and production of progressive and precision punching die of motor core stators and rotors, the company accounts for 70% of the market share of commercial motor die in China and is very much the backbone enterprise of China's die industry.

Hongda is a small and medium-sized manufacturing enterprise with an annual output value of 50 million yuan (around 7 million dollars) and 200 employees. Due to the COVID-19 outbreak, the company's on-duty staff was reduced to 70 employees at minimum, and its production capacity at one point fell to 35% of its average. Hongda tried to resume production as soon as possible to mitigate losses.

Hongda's production director said: "The biggest obstacle to our effort to resume production is personnel management. We need to solve three problems: (1.) How do we ensure that our returning employees are healthy? (2.) How can we help our employees feel at ease and work in a safe environment? (3.) How can we maximize the work efficiency of our employees?

Hongda wanted to improve its management efficiency through a smart and digital means, but it was difficult to rapidly develop and deploy applications through its existing IT architecture. To handle these issues, Hongda turned to Alibaba's supET industrial Internet platform. supET provides many ready-made third-party industrial apps that offer free subscriptions and are ready to use. supET was the best choice to meet Hongda's urgent need to resume production.

To solve the problem of personnel management, Hongda accessed three SaaS apps for production resumption through supET.

Employees were required to report their health status to the company. A mini program for production resumption was developed at Alibaba to work on DingTalk to record the train numbers and dates when employees were returning to work in both an online and real-time manner. The recorded information was compared with public information. Employees who had not yet passed through the quarantine period were supervised. This ensured that the production plan could be promptly executed.

Next, when reporting to work, employees were required to fill in a custom health form to state their health status and whether they traveled to epidemic-stricken regions. This allowed the company to collect statistics on employees' health status on a daily basis. All data can be exported with one click, so the company can have clear and up-to-date information about the health status of its employees.

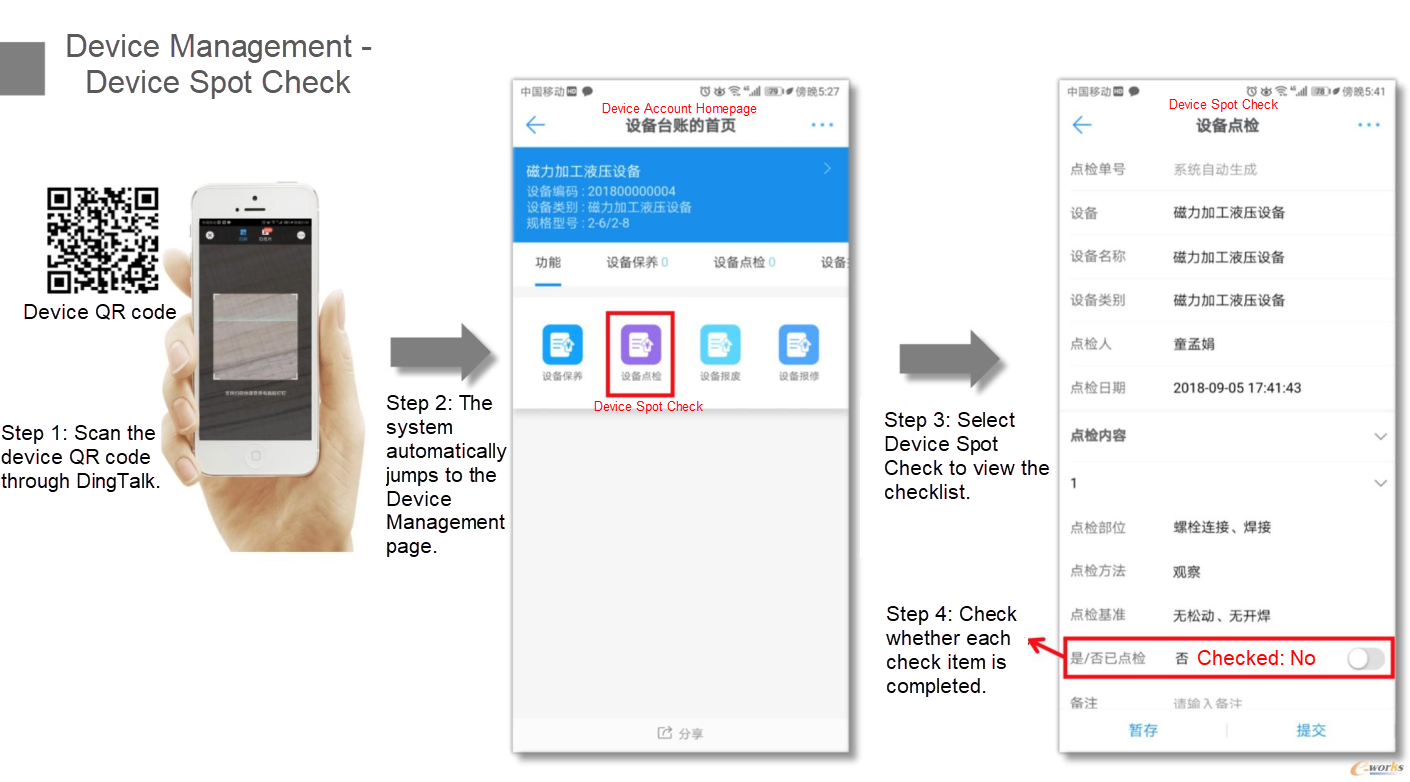

Third, the digital improvements Hongda implemented were not limited to employee health tracking. Previously, the company had employees manually fill in paper records on device disinfection. The process was cumbersome, and offline approval was inefficient. And the lack of timely feedback meant that the equipment administrator and workshop director could not immediately know the device status. Partner Chuanyun developed a device management app on the cloud platform that allows Hongda to manage the disinfection of its 200 processing devices and cutting machines. The workshop director and device owner can now simply scan the QR code on each device to view disinfection information about the device and the related production area. The information is summarized and reported in real time and approved online, which has greatly improved productivity at Hongda.

Subscription to the device management app requires only three steps. First the employee needs to complete real-name authentication, that is verify his or her legal name, to register for a Alibaba cloud account. Second, register with the Alibaba Cloud digital factory. And, last, purchase the required app in the app marketplace. It took less than two days from subscription to the app to launching it online. The app had immediate results. The app helped Hongda improve its management efficiency by more than 50% for production resumption. The app was provided free of charge because of the epidemic.

The COVID-19 outbreak has affected multiple aspects of manufacturing enterprises both in China and abroad. The platform provides a complete set of management apps for production resumption, including emergency shift scheduling, supply chain management, and shipping logistics management, in addition to personnel management solutions. These apps will still be available after the COVID-19 outbreak. These apps assume an important role in the factory's daily production management. The production director of Hongda said that the company hopes to cooperate with Alibaba's Industrial Internet platform to jointly build a die industry platform based on Hongda's years of industrial experience. The platform will connect upstream and downstream resources as well as empower digitization across the industry.

According to Wang Yue, a senior strategic expert at Alibaba Cloud Research Institute, over 80% of Chinese enterprises are small and mid-sized companies These enterprises account for 60% of China's GDP. However, small businesses often bear the brunt of crises and changes in external environments. Digitization gives small businesses hope. However, small businesses cannot reap the benefits of digitization because it is difficult for them to master digital technologies. This is contrary to the potential for inclusiveness of digital technology. Positioned as "industrial Taobao," Alibaba's Industrial Internet platform aims to empower every manufacturing enterprise with products and solutions that meet their business needs. The platform provides comprehensive, lightweight, and easy-to-use services, and improves operations efficiency by more than 30%. Its cost is only 1/5th of that of a conventional solution.

Alibaba Cloud provides solution courses to support production resumption in all industries. Alibaba Cloud has also launched special cooperative policies free of charge to help manufacturing businesses to improve epidemic prevention and quickly resume production.

Check out the original Chinese article here.

While continuing to wage war against the worldwide outbreak, Alibaba Cloud will play its part and will do all it can to help others in their battles with the coronavirus. Learn how we can support your business continuity at https://www.alibabacloud.com/campaign/fight-coronavirus-covid-19

Developing an Infrared Thermometer with an App Based on the WiFi Module of AliOS

2,599 posts | 764 followers

FollowAlibaba Cloud Blockchain Service Team - January 17, 2020

Alex - July 9, 2020

Alibaba Clouder - May 28, 2018

Alibaba Clouder - May 28, 2020

Alibaba Clouder - June 21, 2018

yanmin - June 27, 2019

2,599 posts | 764 followers

Follow Quick BI

Quick BI

A new generation of business Intelligence services on the cloud

Learn More MaxCompute

MaxCompute

Conduct large-scale data warehousing with MaxCompute

Learn More DataWorks

DataWorks

A secure environment for offline data development, with powerful Open APIs, to create an ecosystem for redevelopment.

Learn MoreMore Posts by Alibaba Clouder