The Alibaba Cloud 2021 Double 11 Cloud Services Sale is live now! For a limited time only you can turbocharge your cloud journey with core Alibaba Cloud products available from just $1, while you can win up to $1,111 in cash plus $1,111 in Alibaba Cloud credits in the Number Guessing Contest.

Artificial intelligence (AI) is speeding up production for the Double 11 Global Shopping Festival. Since October 29, the Alibaba AI algorithm has been applied in many textile and garment factories in China. Automatic quality inspection for raw materials, gray cloth, finished cloth, and ready-to-wear garments can be implemented in the factories when using this AI algorithm. The identification accuracy is more than 90%, exceeding the manual version and improving the efficiency five times over.

China is the largest textile and garment production and processing place in the world. However, currently, most quality inspections are carried out manually, which is one of the reasons for low production efficiency. The data shows that the average defect detection rate in a cloth inspector is only 70%. Worker fatigue can cause a range of mistakes during quality inspection.

Low Detection Efficiency from Manual Inspection

Alibaba is the first to apply the AI algorithm to the inspection. According to reports, there are dozens of common cloth types on the market. There are also as many as 100 kinds of cloth defects with similar shapes that are difficult for traditional machine vision technology to find and catch. To accurately identify the subtleties of cloth defects, Alibaba DAMO Academy established the first cloth training set in the industry. Through fully learning the texture features of different types of cloth, AI can correctly identify defects up to one-tenth of the diameter of a strand of hair. The recognition accuracy is above 90%, which is higher than manual inspection of 70%. Moreover, the detection efficiency is improved by five times over.

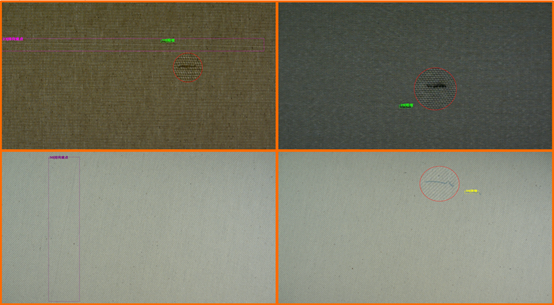

Alibaba AI automatically detects cloth defects with an accuracy of over 90%.

Alibaba AI can implement the quality inspection of mainstream fabrics, such as chemical fiber, cotton, denim, and leather. Its accurate defect classification, such as wrinkles, light spots, and stains from the process of gray cloth to finished fabric, assists quality inspection personnel in making quality control decisions.

Alibaba AI accurately identifies subtle defects in the fabric.

Chu Zhi, an Algorithm Expert from Alibaba DAMO Academy, said, "AI has become an important method for reducing costs and increasing efficiency in traditional industries." Over the past few years, Alibaba has developed AI algorithms for various industries and different scenarios. Now, AI algorithms are widely used in the industrial, transportation, medical care, and education fields.

In 2017, Alibaba Cloud developed the first industrial visual AI solution and gradually applied it to the steel, chemical fiber, and automobile industries. For example, China Solar launched the first AI quality inspection solution for the photovoltaic industry in China, realizing millisecond-level automatic determination of defects of monocrystalline, polycrystalline battery pieces, and components.

Distributed Handling with Alibaba Cloud ACM for DevOps and Microservices

Alibaba Cloud Enables Five Super Data Centers to Support Double 11

2,599 posts | 765 followers

FollowAlibaba Clouder - December 1, 2020

Alibaba Cloud Community - February 14, 2022

Alibaba Clouder - January 19, 2021

Alibaba Clouder - April 8, 2020

PM - C2C_Yuan - April 16, 2024

Alibaba F(x) Team - June 20, 2022

2,599 posts | 765 followers

Follow Black Friday Cloud Services Sale

Black Friday Cloud Services Sale

Get started on cloud with $1. Start your cloud innovation journey here and now.

Learn More Robotic Process Automation (RPA)

Robotic Process Automation (RPA)

Robotic Process Automation (RPA) allows you to automate repetitive tasks and integrate business rules and decisions into processes.

Learn More Offline Visual Intelligence Software Packages

Offline Visual Intelligence Software Packages

Offline SDKs for visual production, such as image segmentation, video segmentation, and character recognition, based on deep learning technologies developed by Alibaba Cloud.

Learn MoreMore Posts by Alibaba Clouder