By Alex Muchiri, an Alibaba Cloud MVP. He is the founder of Itesyl Technologies, a financial data and business banking solutions company.

We are in the middle of an industrial revolution which will completely change how manufacturing works. The term "Industry 4.0" is coined to describe this current revolution that is being brought about by technological advances. Some key trends from the previous industrial revolutions are:

The fourth revolution is a build-up to the third industrial revolution and seeks to enhance the gains from past development in an even smarter way.

This transition in industrial practices is remarkably instrumental to the future of manufacturing. It is a transition fueled by data and machine learning algorithms and as such, is a shift towards the digitization of machines and electronic devices into digital ecosystems. These shifts will impact many industries from healthcare, retail, transportation, communication, energy, and manufacturing, among others. We are already seeing some trends making radical changes to the industry, including:

The above examples are some of the most advanced technologies in use today. While they seem somewhat distinct, improving industrial efficiency requires a mix of several tools at once. Such technology is instrumental to improving speed, agility, reliability, and performance of industrial systems. An organization must prepare in three major aspects:

Digitization is a core strategy for Industry 4.0 covering all aspects of operations in the company structure and horizontally across distributors, suppliers, and partners. There ought to be a way to easily move data across various players. A case ecosystem could include retailers, distributors, transporters, manufacturers, and suppliers connected in one central inventory platform hosted in a cloud platform. Each party has access to crucial data that helps them meet the needs of the other, such as replenishing supplies, offering transportation of goods and supplies, or cutting down on manufacturing. Well-designed systems in manufacturing facilities would also factor-in demand before shutting down production for upgrades and maintenance. Such an ecosystem can recover from interruptions, disruption, and enter new markets.

We are accustomed to constant tracking by our smartphones. This concept is being adopted in the industrial sector as well. When adopted industrially, software systems can track device activity and its interactions with the surroundings and send the data to an analytics platform in the cloud. Analysis of transmitted data can diagnose various parameters such as performance, health and efficiency. By checking the setting of best-performing devices, the performance of a device could be optimized from the cloud. One industry that has benefited from performance enhancement from the cloud is wind power. Big Data analytics help discover the best parameters for all wind speeds and optimize accordingly. Moving forward, there will be further advances in the field to fix devices 'over the air' or even take out mal-functional devices that could impact the performance and health of their peers.

The industrial sector has not always emphasized on customer intimacy and interactions. However, Industry 4.0 is about to change this by getting closer to customers through innovative business models. We have witnessed a fundamental shift in how computing power is sold to customers. Traditionally IT departments procured their own physical hardware; today, the narrative has changed to subscription-based models. Cloud computing has revolutionized how computing works and made it more accessible and affordable. We can anticipate a similar change in heavy industry, in a pay-per-use model: Machine components could be provided by the manufacturer to customers at no upfront cost and the customer would only pay for the services rendered by such components. The use of smart sensors will meter the use of machines in customer premises.

3D printing is an interesting, new trend, whereby customers manufacture products at home. 3D printers are fed with product blueprints and necessary raw material to 'print out' a physical product. The applications could include concrete works, metal printing, plastic moulding, etc. This is still a nascent industry and it is likely that widespread adoption will eventually help people produce items such as toys, artifacts, machine components, or even food from simple blueprints downloaded online.

As we have seen, manufacturing is changing rapidly. In the next 20 years, it will alter most of what is known in today's industry and companies have to adapt. We look at five changes companies must implement to remain relevant in the coming years.

Data is the driving force in this industrial revolution and everyone must be involved in the value chain. That includes the collection, cleaning, processing, analysis and presentation of models. Industrial processes have always produced massive amounts of data, but it has been underutilized. The future demands that such data should not be wasted.

The value of data lies hidden in complex relationships necessitating the use of algorithms to unlock meaning and put data into context. While pre-processing collected data, it should be cleaned to remove noise and errors and also make analysis easy enough. Clean data is easy to interpret using machine learning algorithms helping to unlock hidden insights or discover trends, such as performance, efficiency, and health of machines.

Machine learning and Big Data processing are extremely complex. It would thus be prudent to use third-party data analytics and storage systems for efficient data processing. Vendors such as Alibaba Cloud are leading the way with cutting-edge machine learning solutions that are delivered as a service to thousands of customers connecting millions of devices. As the algorithms sift through billions of data points every day, they continually learn and improve their processing capability.

Using such solutions is cheaper and requires little initial investments in analytics, architectures, research, and implementation. In some cases, it also ensures better security. However, there is a need to consider such options carefully and see how well it suits your organization's needs for security, analysis, and planning.

The internet has made education accessible and affordable. Organizations must prepare their staff by training them on data analytics. Only in this way, companies can access the advanced skills required to analyze industry trends and implement them internally at a far lower cost.

It could also be an avenue for collaboration between the industry and universities. In major cases, there are sophisticated open-source tools that do much of the heavy lifting and only require an understanding of how to work with them.

While it may seem counter-productive to share data with competitors, machine learning algorithms work best when the data is massive. Cloud-based analytics could collect data from all components produced by a given manufacturer to understand how they perform and provide better feedback on improvements.

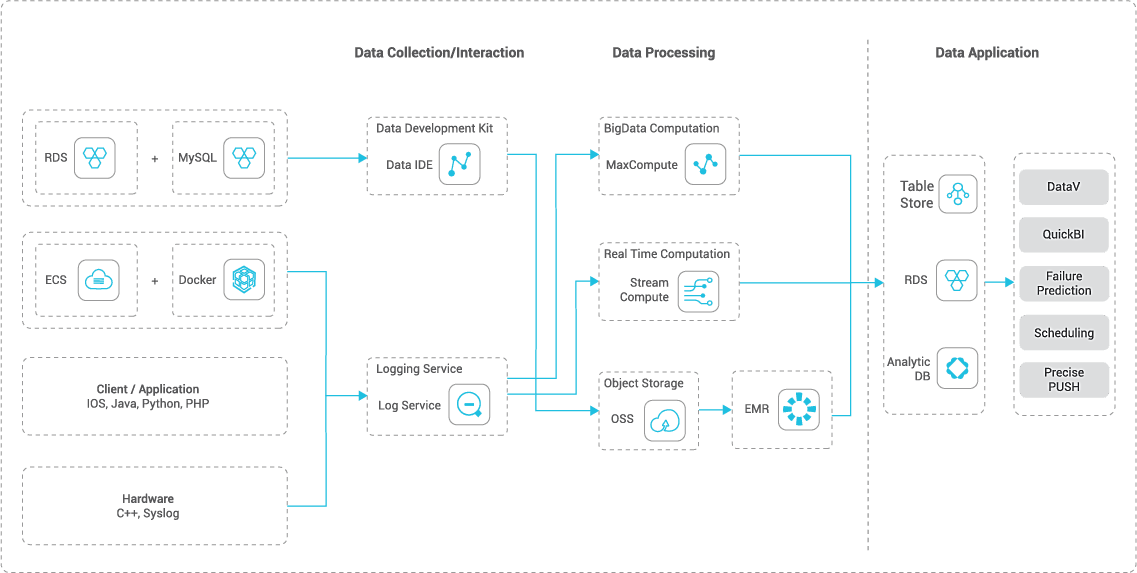

Alibaba Cloud has invested heavily in Big Data solutions, with a wide range of solutions for fast, efficient Big Data development and intelligent analysis. The platforms support batch, interactive, stream, and graph computation, as well as large-scale machine learning on heterogeneous cloud-scale data centers

Alibaba Cloud Big Data tools can help with:

Below are some of the products you cloud plugin and use today:

Elastic MapReduce is a data processing platform with a fast, high throughput engine for companies producing massive amounts of data. The insights derived from Big Data analytics are real-time. Furthermore, provisioning distributed Hadoop Clusters is very easy.

MaxCompute is a large-scale data warehousing solution for general-purpose data processing. It is a secure way to import solutions and provide offline data analysis capability.

DataWorks is a Big Data platform launched by Alibaba Cloud. It provides one-stop Big Data development, data permission management, offline job scheduling, and other features.

DataWorks works straight 'out-the-box' without the need to worry about complex underlying cluster establishment and operations and management.

Quick BI allows you to perform data analytics, exploration and reporting on mass data with drag-and-drop features, and a rich variety of visuals. Quick BI enables users to perform data analytics, exploration, and reporting and empowers enterprise users to view and explore data and make informed, data-driven decisions.

DataV is a powerful yet accessible data visualization tool, featuring geographic information systems allowing rapid interpretation of data to understand relationships, patterns, and trends. All packed into a user-friendly interface.

By integrating live dashboards, DataV can simultaneously present and monitor business data. This data-driven approach enables well-organized data mining and analysis, allowing the user to seize new opportunities that otherwise might remain hidden.

For companies to survive Industry 4.0, they must be flexible and competent to adapt. As such, they should have a complete understanding of how industry changes will impact their business. Experimenting with new technologies such as Alibaba Cloud Big Data solutions will place them at the forefront of the revolution.

agilewiz - March 9, 2020

ApsaraDB - January 3, 2024

digoal - February 13, 2025

Alibaba Cloud Community - September 13, 2024

Alibaba Clouder - August 9, 2019

Alibaba Container Service - April 28, 2020

Big Data Consulting for Data Technology Solution

Big Data Consulting for Data Technology Solution

Alibaba Cloud provides big data consulting services to help enterprises leverage advanced data technology.

Learn More MaxCompute

MaxCompute

Conduct large-scale data warehousing with MaxCompute

Learn More Big Data Consulting Services for Retail Solution

Big Data Consulting Services for Retail Solution

Alibaba Cloud experts provide retailers with a lightweight and customized big data consulting service to help you assess your big data maturity and plan your big data journey.

Learn More Hologres

Hologres

A real-time data warehouse for serving and analytics which is compatible with PostgreSQL.

Learn MoreMore Posts by Alex